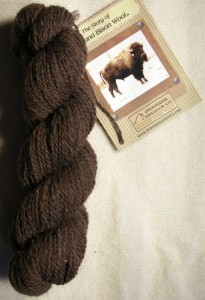

If Montana Sweater knows one thing…it’s bison yarn. In one way, it is the reason we exist. Every winter, I relieve numerous bison hides of their fluffy down and fiber to be processed into yarn. There is an entire story about how one day a bison hide landed in my garage, how I worked with an area rancher to find the right pair of shears to clip the hair off the hide, and how I learned to let the hide dry enough to facilitate easy shearing, but not leave it so long that it gave off the oh-so fragrant aroma of stink. It took many mistakes to get a system down for preparing a bison hide for shearing. It involved finding ways to lift it with a pulley since I ran out of friends, neighbors, and loved ones to help me manually hoist the raw-hide up on top of a barrel form (they got tired of blood stained clothing…sorry to gross you out). It involved finding the right tools to comb and clean the hair of vegetation and poo before shearing, and it involved a trip to the local ranch store to pick out my Christmas present…a pair of lined Carhart overalls and insulated boots for the chilly days I’d be working ALONE in the garage. There isn’t any other way to get the wonderful soft bison down. No store where I can order a pound or two. It takes a certain kind of crazy to want to get a fiber like this, and I guess I qualify. The truth is, after I got used to the smell, I realized how privileged I was to have access to such a fantastic creature. To actually comb through a hide of healthy bison hair is something most people will never get to do. I noticed differences in quality of fiber from animal to animal. Some hides just keep offering up one fantastic patch of down after another, while others are more sparse in their offerings. I noticed that usually one side of the hide is thicker than the other as if the animal might have lay on one side more than the other. All bison wallow, that is, from time to time they roll around like dogs on their backs in a divit of dry dirt, kicking delightedly with legs in the air. This means I must check how much dirt is stuck deep down in the fibers. A powerful vacuum helps get the dirt out so my shears don’t malfunction every five minutes…which means I learned to have back up blades ready to replace dull shears that quit on me after one swipe through a particularly dirt filled patch of hide. It takes about four days to thaw a frozen hide (the way it is delivered), and afterwards about 2 hours to prepare and properly shear it. If the fall/winter has been particularly cold, it will have inspired the bison to grow more and longer fibers which means I get about 4lbs of usable fiber per hide. And then we can start deducting, because after the fiber has been washed, dehaired ( a process that takes out the coarse fibers and leaves the fine fibers behind), carded, drafted, and then plyed into yarn, about 2lbs of useable fiber remains. In order to extend the life of a winter’s worth of fiber harvesting I decided to blend it with other area wool and alpaca ranches and their fibers. This way everyone gets to get in the act, and the cost per oz is more affordable for the market. I work with two Montana Mills to bring my bison yarn dream to life: 13 Mile Lamb & Wool, and Going-to-the-Sun Fiber Mill. Currently, the only way to try my yarn is to purchase it directly from Montana Sweater Co. There are several varieties and blends. We hope you’ll try a skein and knit a part of the wild west into a hat, a pair of mitts, or scarf.